Discover how AI agents are reshaping the manufacturing operating model

Hi, I’m Alison!

Share your details, and I’ll give you a call in minutes to see how we can assist.

The Ultimate Guide to Procuring Generative AI for Your Manufacturing Company

Table of Contents

ToggleEffective collaboration with suppliers is more than just a business transaction for manufacturers; it’s a strategic partnership that underpins operational success. Rather than focusing solely on price negotiations and delivery schedules, strong supplier relationships create a foundation for better efficiency, cost reduction, and continuous innovation. As supply chains become increasingly global and markets grow more unpredictable, a company’s resilience and ability to adapt quickly to changes are directly tied to how closely it can work with its suppliers.

The Challenges of Managing Your Supplier Relationships

Supplier management involves numerous challenges that can have a significant impact on manufacturers if not addressed effectively.

Challenge | Impact on operations | Affected Department(s) |

Manual Processes | Delays in communication or missed follow-ups can lead to production delays, increased costs, and even stockouts, all of which directly affect the manufacturer’s ability to meet customer demand. | Procurement, Production Planning |

Inconsistent Communication | Poor communication can cause misunderstandings, delayed shipments, and increased lead times, ultimately disrupting production schedules and damaging supplier trust. | Procurement, Production Planning, Sales |

Difficulty in Managing Supplier Performance | Inadequate supplier performance management can lead to unreliable deliveries, compliance issues, and increased risks, which may compromise the quality and continuity of supply. | Procurement |

Lack of Real-Time Visibility | Limited real-time data on supplier activities makes it difficult to anticipate issues and adjust production plans accordingly. | Production Planning, Procurement |

Inefficient Document Handling | Managing compliance documents manually leads to delays, missing paperwork, and errors, which can impact production timelines and create bottlenecks. | Procurement, Finance |

Limited Risk Assessment | Assessing supplier risks without automated tools is time-consuming, and often leads to reactive rather than proactive risk management. | Procurement, Finance |

Supplier Capacity Constraints | Difficulty in understanding supplier capacity and workload can lead to overcommitments or missed deadlines, affecting production schedules. | Production Planning, Procurement |

Complex Supplier Networks | Dealing with multiple suppliers across various regions introduces complexity, increasing the chances of communication errors and delays. | Procurement, Production Planning, Sales |

Benefits of Using Autonomous AI Agents for Supplier Management and Collaboration

Autonomous AI agents bring multiple benefits to procurement teams, including automating repetitive tasks, improving communication, monitoring risks, providing data-driven insights, and reducing costs. These capabilities lead to greater procurement efficiency, stronger supplier engagement, fewer disruptions, and significant cost savings by enhancing operational performance and supplier relationships.

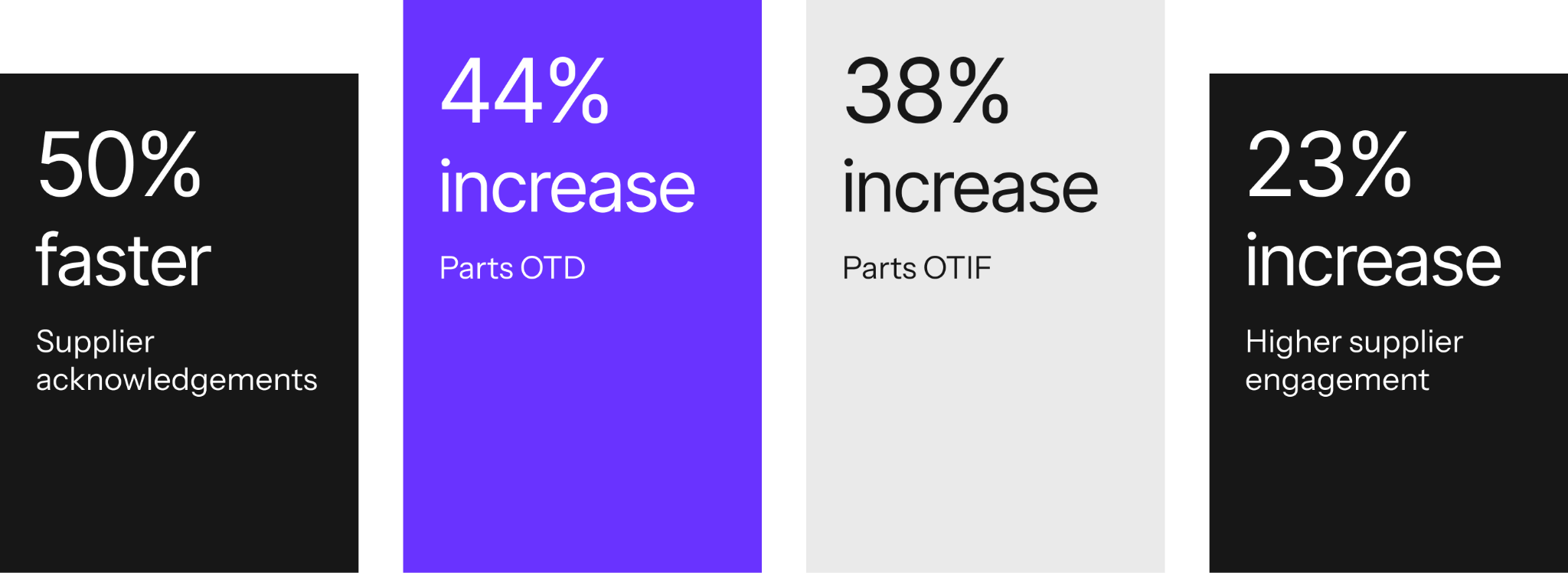

Faster Supplier Acknowledgments: Leveraging automated workflows such as order confirmations and order revision alerts, Autonomous AI Agents help speed up supplier response times, ensuring that suppliers acknowledge orders promptly. This allows manufacturers to gain greater visibility into the supply chain and make faster decisions.

Enhanced On-Time Delivery (OTD) for Parts: By using features like supplier scorecards, supplier risk alerts, and shipment tracking, manufacturers can ensure that suppliers deliver parts as scheduled more consistently. This reduces production delays and keeps manufacturing schedules on track.

Improved On-Time In-Full (OTIF) Performance: With automated processes for shipment tracking, purchase order delay alerts, and stock out alerts, Autonomous AI Agents enable manufacturers to receive the right quantities at the right times. This ensures reliable deliveries, leading to fewer production stoppages and optimized inventory management.

Higher Supplier Engagement: Autonomous AI Agents provide tools such as the supplier spend report, purchase order payment forecast, and work order risk visibility, fostering better communication and engagement with suppliers. With streamlined processes and better access to information, suppliers are more involved, leading to stronger relationships and improved alignment with business goals.

Use Cases Of Agent PO For Better Supplier Relationship Management

Agent PO, with its combination of automated workflow use cases and decision intelligence use cases, is transforming supplier relationships for CPOs and Heads of Procurement. Here’s how Agent PO contributes to improving supplier collaboration:

- Missing Document Alerts:

- User Benefit: Streamlines compliance by automating the process of identifying and requesting missing documents.

- Business Impact: Minimizes idle inventory and reduces costs by ensuring compliance documents are available when needed.

- How the Feature Works: Agent PO automatically identifies missing compliance documents for a purchase order, requests them from the supplier, and sends follow-up reminders as needed.

- Automated Order Confirmation Follow-Ups:

- User Benefit: Reduces the administrative burden of manually following up with suppliers for order confirmations.

- Business Impact: Fewer delays and more predictable supply chain operations.

- How the Feature Works: Agent PO sends automated follow-up emails to suppliers if order confirmations are not received within a specified timeframe.

- Supplier Performance Monitoring and Alerts:

- User Benefit: Provides real-time tracking of supplier performance, reducing inconsistencies and manual monitoring efforts.

- Business Impact: Improved supplier reliability and reduced risks of supply chain disruptions.

- How the Feature Works: Agent PO aggregates supplier performance data and generates alerts for deviations from expected metrics.

- Proactive Risk Alerts:

- User Benefit: Enables procurement teams to mitigate risks before they become major issues.

- Business Impact: Helps maintain a reliable supply chain and reduces costly disruptions.

- How the Feature Works: Agent PO monitors various risk indicators, such as financial instability or compliance breaches, and sends real-time alerts when risks are detected.

- Automated Shipment Tracking and Notifications:

- User Benefit: Ensures procurement teams stay informed of shipment status without manual tracking.

- Business Impact: Minimizes production disruptions and ensures timely availability of materials.

- How the Feature Works: Agent PO integrates with logistics systems to track shipments in real time and automatically notifies stakeholders of key milestones or delays.

- Seamless Supplier Communication:

- User Benefit: Improves communication efficiency by handling supplier interactions automatically while maintaining a human-like experience.

- Business Impact: Builds trust and reduces communication delays, leading to more efficient supplier collaboration and reduced response times.

- How the Feature Works: Agent PO seamlessly communicates with suppliers through integrated communication channels, automating responses and ensuring that suppliers are unaware they are interacting with an AI agent.

The Ultimate Guide to Procuring Generative AI for Your Manufacturing Company

Table of Contents

Toggle

Author:

Kevin Musprett

Head of Growth at Kavida.ai

Kevin drives GTM at Kavida, an AI agent used by manufacturing purchasing teams so they never miss a critical order from suppliers. Kevin dedicates himself to building and scaling kavida.ai to become the PO management platform of choice for an addressable market of over 15 million users.

Related articles

The ERP Migration Myth: How Agentic AI Unblocks Value Across Fragmented Systems

Procurement leaders today need more than just efficient workflows—they need insights that drive smart decision-making. For decision makers...

Cleaning and Consolidating Parts Data Across ERPs with AI Agents

Procurement leaders today need more than just efficient workflows—they need insights that drive smart decision-making. For decision makers...

AI Intimacy: How Supply Chain Agents Adapt to You

Procurement leaders today need more than just efficient workflows—they need insights that drive smart decision-making. For decision makers...