Discover how AI agents are reshaping the manufacturing operating model

Hi, I’m Alison!

Share your details, and I’ll give you a call in minutes to see how we can assist.

The AI agent for intelligent operations.

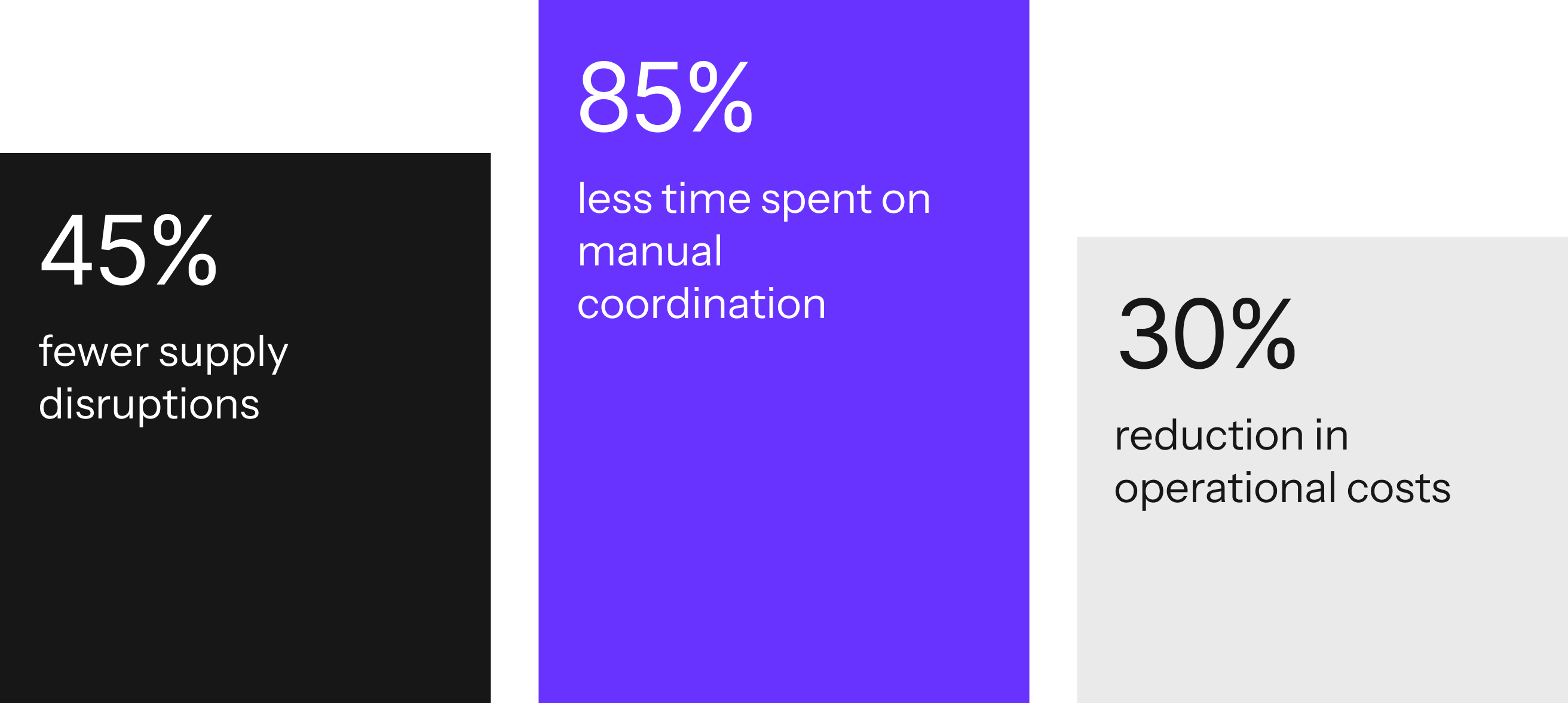

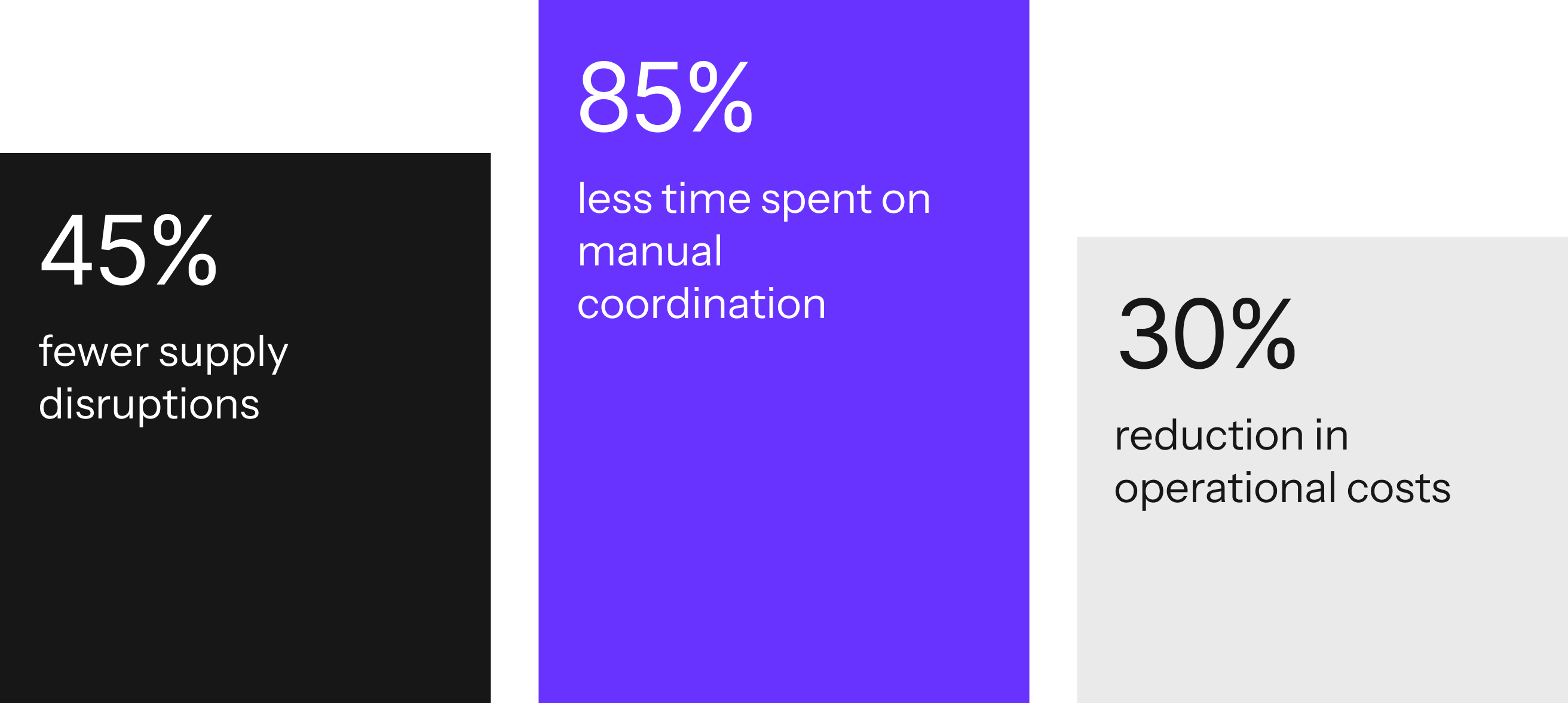

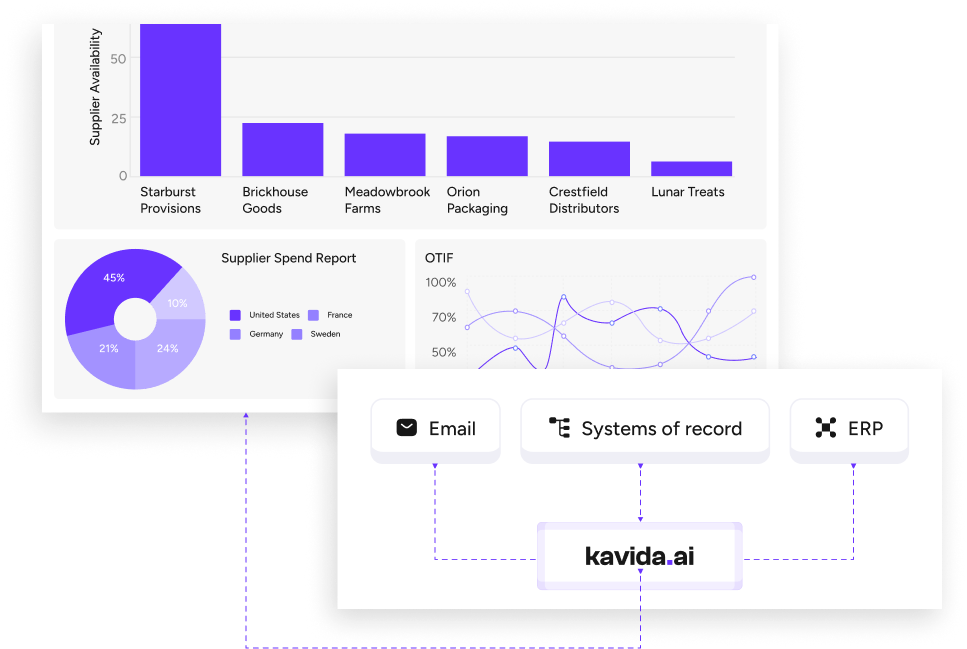

Keep operations running at peak efficiency without the constant firefighting. Kavida gives you real-time visibility, predictive alerts, and automated tracking to eliminate last-minute surprises and keep production on schedule.

Automate tasks, reduce admin work, and optimize inventory to prevent stockouts and control costs. With centralized data and actionable insights, you make faster, smarter decisions – ensuring a resilient, scalable operation that stays ahead of disruptions.

Efficient operations, uninterrupted production.

Kavida automates critical yet monotonous procurement processes, creating intelligent workflows to keep your production line running smoothly and efficiently.

Your AI agent monitors external supply chain risks, supplier performance, and stock levels in real-time, preventing disruptions, costly stockouts, and reducing excess inventory while automating order confirmations, document management, and routine acknowledgments. With tasks like chasing suppliers or managing paperwork offloaded, your team can now focus on strategic priorities like cost optimisation and wider business objectives.

100+ automations to simplify complex operations.

Automations to eliminate time-consuming and inefficient workflows, so you can focus on operations optimisation, not micromanaging processes.

Monitors real-time location of shipments, containers, and couriers.

Automatically requests, tracks, and validates aerospace compliance docs.

Identifies potential supplier delays from issues, port congestion, or risks.

Monitors stock levels and sends alerts when inventory needs attention.

Enables stakeholders to query complex ERP data using plain English.

Balances stock levels while ensuring compliance requirements are met.

Follows up for documents and sends received documents to the relevant teams.

Measures OTIF delivery, changes, and responsiveness for better insights.

Integrates with multiple systems of records to provide a single source of truth.

Power your operations with faster, data-driven decisions.

Real time multi-tier supply chain risk monitoring.

Kavida’s 24/7 real-time risk intelligence allows you to easily monitor and receive real-time alerts for any potential risks to your network of all primary and sub-tier suppliers and shipments preventing last minute surprises.

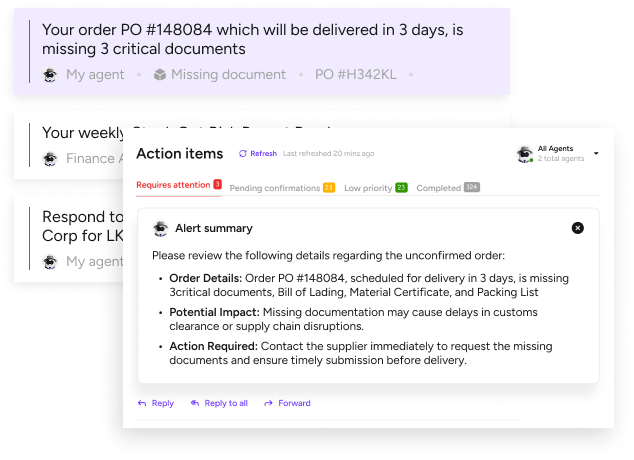

Intelligent alerts and predictive insights to prevent disruptions.

With Kavida, you get real-time alerts and predictive insights that keep you ahead of supplier delays, logistics bottlenecks, and operational risks. Anticipate disruptions, act early, and stay in control—so your operations run smoothly, without unnecessary setbacks or stress.

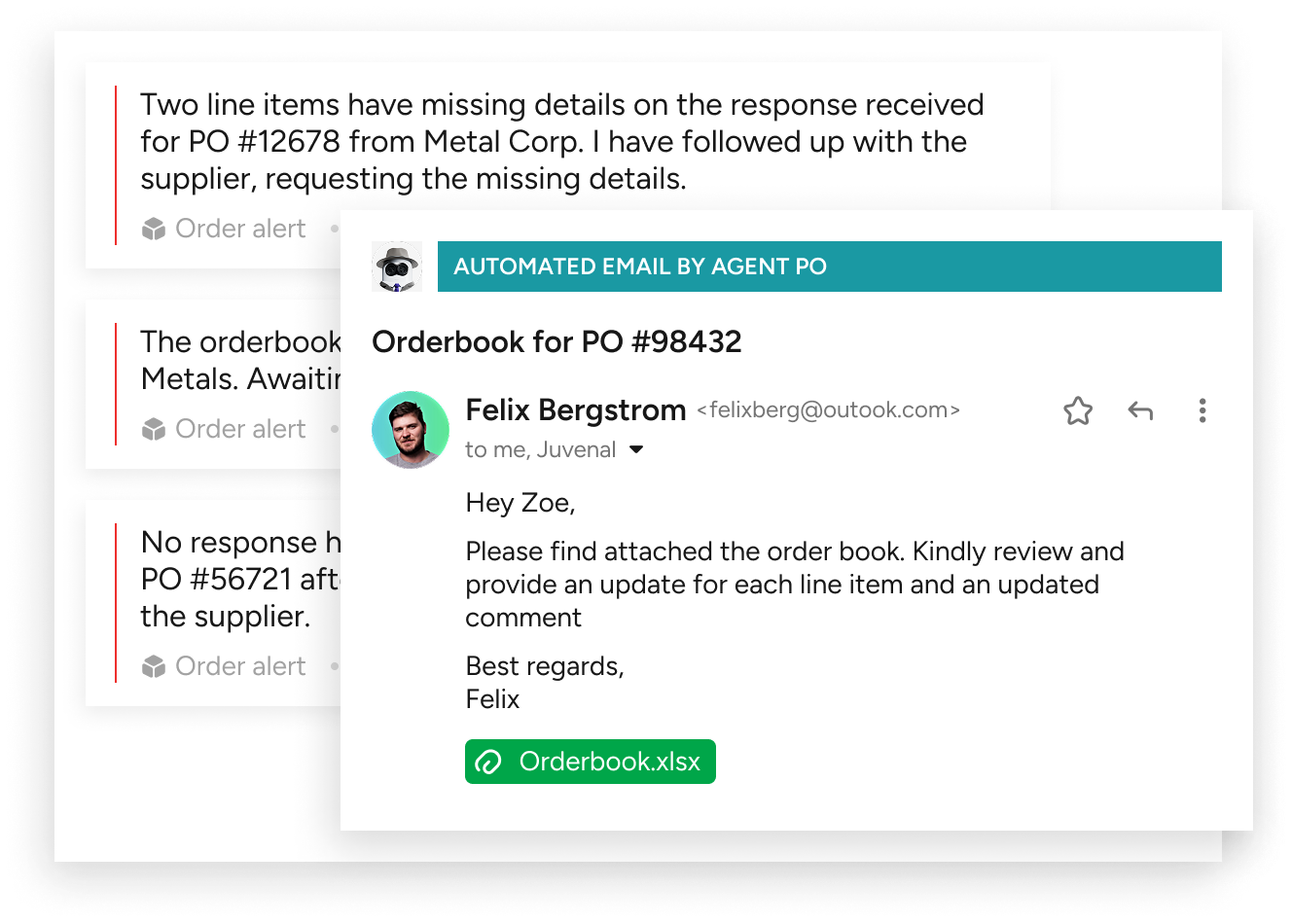

Automated order tracking and supplier coordination.

Agent PO automatically dispatches order tracking, analyzes supplier responses, and turns them into actionable tasks – coordinating suppliers and communicates with the ERP and SCM and other sources eliminating manual inefficiencies, and ensuring real-time order tracking while freeing up your team from administrational work.

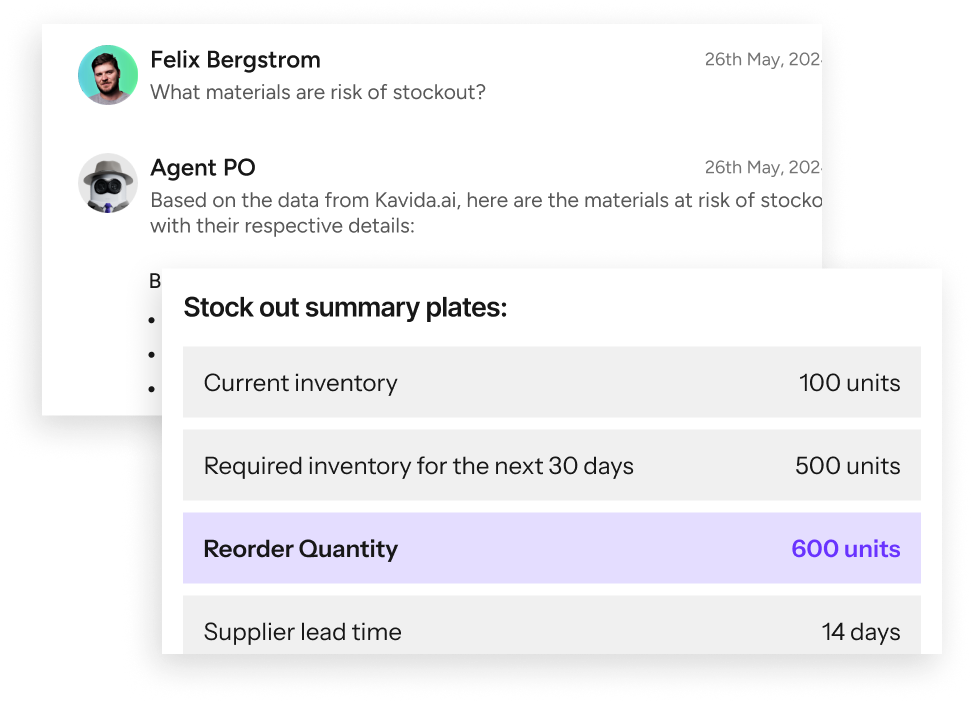

Optimize inventory, eliminate stockouts, and have lean operations.

Get real-time inventory tracking, predictive insights, and automated alerts – so you always have what you need, when you need it. No more shortages, no more excess. Just complete control and uninterrupted operations. Giving you right balance between lean operations and product availability

Working capital and inventory optimisation.

Your AI agent tracks stock levels, automates replenishment, and predicts shortages—helping you prevent costly stockouts and delays while maintaining lean inventory levels.

Our AI agents power manufacturing supply chains.

Quick time to value use cases to test out Agent PO using sample data sets.

How Village Gourmet Transformed Their ERP into a Cognitive Tool - E21

Village Gourmet faced significant challenges due to their ERP’s limited and siloed capabilities. With a fragmented system and no cross-referencing of data streams, the team struggled to reduce their risk of stockouts.

From ERP Chaos to Clarity: AlE’s Journey to Instant Data Access - EFACS

Discover how AlE transformed their ERP landscape with Al, breaking down collaboration barriers, eliminating training woes, and providing instant access to critical information through natural language queries.

How Dyer Engineering Eliminated Cross-Departmental Bottlenecks - EPICOR

Dyer Engineering, with over 200 employees across production, engineering, warehousing, and finance, faced challenges with their ERP system. Despite it being an essential system of records, the ERP was hard to navigate…